The Design Thinking Action Lab online class has created the largest design team in the world, bringing together 45,000 students in fields ranging from engineering to education to business. Class member Vignesh Vishwanathan, an engineering student at the University of Illinois at Urbana-Champaign, sees many connections between design thinking and his internship designing parts for electric racing vehicles.

Read more student profiles »

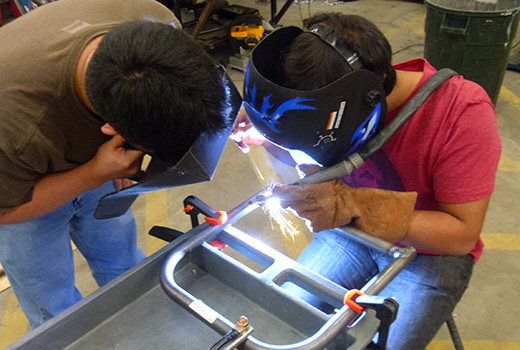

Vignesh Vishwanathan (right) welds the structure of the chassis for one of Illini Formula Electric's electric racing vehicles.

Chennai, India

Sophomore mechanical engineering major, University of Illinois at Urbana-Champaign

Vignesh Vishwanathan has been using the design thinking process for the last year, but didn’t realize it until he enrolled in the Design Thinking Action Lab course. As an engineering student at the University of Illinois at Urbana-Champaign, Vignesh interned during the school year at Illini Formula Electric – a student group that designs and builds competitive electric racing vehicles.

“Every part of the car has to be designed within given specifications,” said Vignesh, a rising sophomore mechanical engineering major. “My job is to integrate all these parts to the chassis and make sure they work well.”

Vignesh said that when he designs, both in his internship and in his undergraduate engineering studies, he uses a similar method to the design thinking process, analyzing the true problem at hand, building prototypes, and testing the results. “But I didn’t know it was a well-known and documented process,” he said.

During the first week his freshman year, while navigating an activity exposition on campus, Vignesh approached a man riding a bike through the crowd. “I asked him, ‘Do you know of any organizations working on cool projects here?’ He said, ‘Follow me.’ It turned out he was the head of the race car organization.”

Motivation and the passion to learn were also key once he began the internship. Vignesh and his fellow new interns attended meetings and did a lot of “standing and watching” while others designed and assembled parts. One day, he spoke up.

“I said, ‘I’m just waiting here, is there anything that I can help you all with?’” Before long, Vignesh was working alongside the seasoned interns. “The more you asked, the more they gave you an opportunity.”

When he returns to school in the Fall, he will head the chassis team for Illini Formula Electric.

Vignesh said that the most important lesson he’s learned in the course, one that he can apply to his work with electric racecars, is to document his design process. He now has a book where he can keep notes.

“My process was always in my mind,” he said. “I think because I wasn’t noting things down anywhere, I would miss certain points here and there. This has taught me the need to document it.”

He also said that he will be able to teach the design thinking process to his chassis team to improve the overall quality of their engineering work.

“This class teaches you how to organize design, and organize thought in order to design better products and reach consumers,” he said.

Vignesh’s interests extend beyond engineering and include computer programming and entrepreneurship. This summer, he is taking a Stanford startup engineering class on Coursera to brush up on his coding skills. When he begins school, he will conduct research with the Autonomous Materials Systems lab, and start a course on technology commercialization.

“Engineering changes constantly. The moment you stop innovating or learning, you become antique,” he said. “I’m trying to keep my options open and be prepared for the future.”

Read more student profiles »